Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [376] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 2

Members Online: 0

Total Members: 8,394

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,394

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

|

Building a roaster, looking for advice

|

|

| hbuchtel |

Posted on 02/07/2006 5:18 AM

|

|

Newbie  Posts: 11 Joined: January 02, 2006 |

UPDATE: Spring Festival is almost over and people are starting to re-open their stores so I FINALLY was able to buy the missing parts, namely the frame. I got everything put together and working but wouldn't you know it my variac pooped out (could have been my wiring) and I have to exchange it for a new one before I can start. Unfortunately the owners of the store where I got it have not returned to work so I'll have to wait for them. Soon soon . . . Henry |

|

|

|

| Mike |

Posted on 02/07/2006 2:17 PM

|

|

1/2 Pounder  Posts: 283 Joined: October 24, 2005 |

Have you dis-assembled the variac to see what happened to it? Mike B) |

|

|

|

| hbuchtel |

Posted on 02/07/2006 11:35 PM

|

|

Newbie  Posts: 11 Joined: January 02, 2006 |

Quote Mike wrote: Have you dis-assembled the variac to see what happened to it? Mike B) I haven't. I don't want to do anything to it in case it voids my 'warranty' What happened was that one of the connections on the front of the variac (on the 'output' side) got hot enough to melt the plastic housing. At this point all the wires (between the wall and the heater) were warm.  It happened while I had the variac at it's highest output (250VAC) connected to the 2kW nicrome (?) heating element in the rectangular base. This has never happened when using my 1200W popper, or while connected to the 2kW heater in the circular base (see pictures above). The wires that I connected to the variac are rated at 250V/10A, the variac is rated at 250V/12A/3kW, the heating element was 2kW . . . is there a problem here? I confess I don't understand how amps relate to voltage, wattage, etc. Henry |

|

|

|

| metal |

Posted on 02/08/2006 3:57 PM

|

|

1/4 Pounder  Posts: 81 Joined: February 05, 2006 |

The formula: Volts X AMPs = Watts...I think you were pushing 3000 watts through wire that was designed to handle 2500 after the wire met the threshold it also became a heating element. I am surprised the 2kw element was not the meltdown point. oops! @ 250 volts your element is designed to only pull 8 amps threshhold. |

|

|

|

| hbuchtel |

Posted on 02/09/2006 6:41 AM

|

|

Newbie  Posts: 11 Joined: January 02, 2006 |

Quote Metalcrafter wrote: The formula: Volts X AMPs = Watts...I think you were pushing 3000 watts through wire that was designed to handle 2500 after the wire met the threshold it also became a heating element. I am surprised the 2kw element was not the meltdown point. oops! @ 250 volts your element is designed to only pull 8 amps threshhold. Thanks for your reply...looks like I should avoid using the full 250V. I have to wait a couple days to get my variac fixed (till the next full moon, to be precise) so I have time to ruminate. Perhaps the heating element would have burnt out in time, but the burning plastic smell alerted me before that happened. Any idea why only one of the connections on the variac got that hot? Henry |

|

|

|

| hbuchtel |

Posted on 02/09/2006 6:50 AM

|

|

Newbie  Posts: 11 Joined: January 02, 2006 |

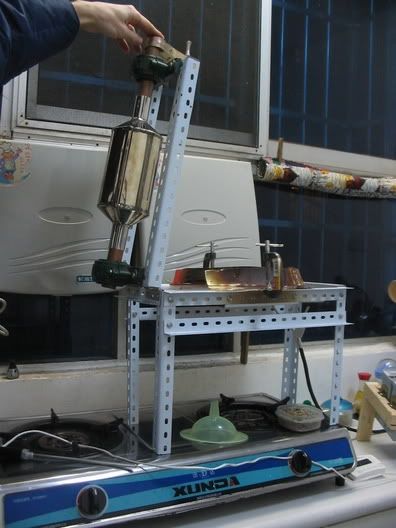

*sigh* Well, I'm out of roasted coffee, and with the variac out of commission I can't use my popper (I've drank enough of 4 minute coffee). So into the 'Erector Set Barbie' (as I've dubbed her) goes 100g of Yunnanese . . . I collected plenty of temp data with a constant 220V, and I think I can get a good profile with a cool start and unplugging the heater after 1st crack . . . I'd better, as I'm very short on green at the moment! Wish me luck . . . Henry |

|

|

|

| hbuchtel |

Posted on 02/10/2006 2:07 AM

|

|

Newbie  Posts: 11 Joined: January 02, 2006 |

well that was bizarre. I never realized beans contained some much moisture! With fluid bed roasting I don't see any of it, but with this this drum roaster it was condensing in the long tubes at the sides and on the body of the thermocouple. So much water that it dripped onto the table! So the beans steamed for about 10-12 minutes, I wasn't hearing anything like 1st crack, so when I started smelling some smoke (not burning plastic this time!) I pulled the plug for two minutes. I was originally planning to end at second crack but was worried I wouldn't hear it so just ended at 20 minutes. It took 3-4 minutes to get all the beans out and cool them. The beans came out a dark brown, similar to what I would expect from a pre-second crack on the popcorn popper. I kept on messing with the tc (trying to push a stuck bean into the drum) so the temperature readings don't mean much. I just finished a cup of French Press, which was light and pleasant, no off flavors. I've never roasted this particular batch of beans before (a sample from an on-line seller) so I don't know what to expect, but I'm quite pleased with the result. I'd better be, as I'll be drinking this till more beans arrive next week! Ok, I should stop avoiding this (seeing metalcrafter's amazing roaster has me kinda embarassed). Here are a few pictures-  "Erector Set Barbie" in all of her glory  "Dumping mode" (frenzied shaking and shouts of dismay not shown)  Drum over Heating element. Henry |

|

|

|

| Dan |

Posted on 02/11/2006 9:31 AM

|

|

1 1/2 Pounder  Posts: 1662 Joined: October 24, 2005 |

Henry, Impressive setup! Nice 'sample roaster' action, too. That makes yours the 4th or 5th sample roaster made from scratch. I'm tellin' ya, sample roasters are the way this hobby is going. Anyway, the long copper snouts are condensing the steam. Could you shorten them up? I think those huge bearings can handle a little heat. Perhaps if they are shorter you'll have less drips, more sound, and easier TC locating. Some vertical sheet metal walls at either end of your heating element could keep heat off the bearings, too. nice use of perfed metal. I call it 'Erector Set for Men!" Looking good! |

|

|

|

| hbuchtel |

Posted on 02/11/2006 11:39 AM

|

|

Newbie  Posts: 11 Joined: January 02, 2006 |

Quote Dan wrote: Henry, Impressive setup! Nice 'sample roaster' action, too. That makes yours the 4th or 5th sample roaster made from scratch. I'm tellin' ya, sample roasters are the way this hobby is going. Anyway, the long copper snouts are condensing the steam. Could you shorten them up? I think those huge bearings can handle a little heat. Perhaps if they are shorter you'll have less drips, more sound, and easier TC locating. Some vertical sheet metal walls at either end of your heating element could keep heat off the bearings, too. nice use of perfed metal. I call it 'Erector Set for Men!" Looking good! Thanks Dan! I've got another week before school starts so I'm hoping I'll have time for some of the improvements you mentioned - especially shorten the tubes and get some kind of cover to keep heat in . . . though it is kinda nice in the winter! I'm liking the hand-turning so far. Not too tiring, and maybe even a bit therapeutic! Henry |

|

|

|

| hbuchtel |

Posted on 03/04/2006 10:02 AM

|

|

Newbie  Posts: 11 Joined: January 02, 2006 |

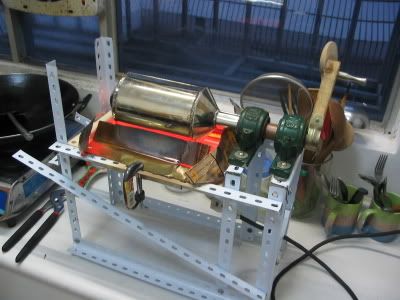

I've been getting great results, the best tasting coffee I've ever roasted, but for various reasons (especially the time it took to get all the beans in and out) I made some changes. I was inspired by the pictures of the roaster on this page. The two bearings on the right hold a copper tube which the drum is mounted on. The bits of sheet metal are my attempt at directing the heat to the drum. I am eager to get an enclosure around the drum but should wait for the design to stop changing. I took a hacksaw to one end (a really ugly job, won't show a picture) now dumping the roast only takes a couple seconds. I use the pliers shown in the picture (lower left) to slide the drum off the axel. I'll have to use a slightly smaller batch then I had been, at 150g it develops what I'm choosing to consider a feature: "Automatic Sample Display". . . meaning that it will occasionally dump out a bean. I've only finished one roast so far, it seemed to pass through the steaming stage quite quickly. The roast turned out very even and took about 16 minutes to an early 2nd crack. The beans smelled great (I never got this smell with the hot air roaster), I'm looking forward to trying them tomorrow.  Henry |

|

|

|

| Mike |

Posted on 03/04/2006 12:39 PM

|

|

1/2 Pounder  Posts: 283 Joined: October 24, 2005 |

henry, Sounds like it is working for you. Really neat project, the modifications so far seem to be going in the right direction. When you get to the addition of sheet metal, I'll bet it comes together nicely. Mike B) |

|

|

|

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman