Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 1

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

Page 1 of 2: 12

|

|

Can First Crack be detected by Measuring the Intake Air Temp?

|

|

| SkipG |

Posted on 10/22/2021 7:09 PM

|

|

Newbie  Posts: 11 Joined: April 16, 2021 |

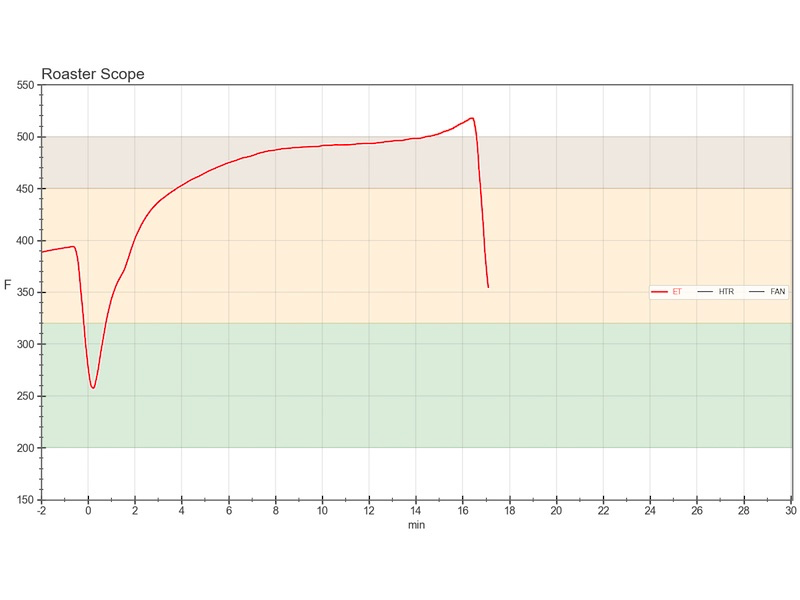

I have been roasting a while with my modified Gene Cafe with a dimmer to control heater power, and a thermocouple to monitor the intake air temp. With preheat to 392F and increasing the power to 84 to 88%, depending on ambient temperature, at 1:20, I am seeing the exhaust temp returning to 392F around 5:40, and hitting reaching 450F about 15:00. The intake temp climbs to 490F by about 9:00 minutes, and slowly climbs 500F by about 12:00 minutes. The reason for this post is that, with this profile, I am seeing a pronounced rise in the intake air temp around 14 minutes with constant power since very early in the roast as shown in the attached Artisan graph of the intake air thermocouple. The first time I saw it, I attributed it to chaff partially obstructing the exhaust, and dropped the roast to prevent the temperature from going out of control. Lately I thinking that the rise in temperature is due to the beans going exothermic. I decided to let it go a minute longer, and the temperature looks as though it might be stabilizing, as the ROR started decreasing. So do you think I'm seeing the results of First Crack? I think the timing is too consistent to be chaff-related. I see it with Columbian Supremo, Kenya AA and Ethiopian Moka Harar (which has a lot more chaff than the Supremo). Thanks!

SkipG attached the following image:

Gene Cafe (modified), Kalita Pour Over setup.

|

|

|

|

| renatoa |

Posted on 10/23/2021 7:11 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Yes, it could be very noticeable, as shown here: https://homeroast...post_74130 For the Gene case, the exhaust temperature should show this even more clear than intake. |

|

|

|

| SkipG |

Posted on 10/24/2021 5:44 AM

|

|

Newbie  Posts: 11 Joined: April 16, 2021 |

I actually installed a cheap bead thermostat (pack of 6 for $10) but the fluctuations were not a good match for the other thermocouple and I took it out. I may get one thats similar to the intake one. The GC thermocouple isn't that responsive so I'm not seeing it there. That is an interesting thread. Thanks for the link, and for the reply. --Skip Gene Cafe (modified), Kalita Pour Over setup.

|

|

|

|

| SkipG |

Posted on 11/29/2021 11:13 AM

|

|

Newbie  Posts: 11 Joined: April 16, 2021 |

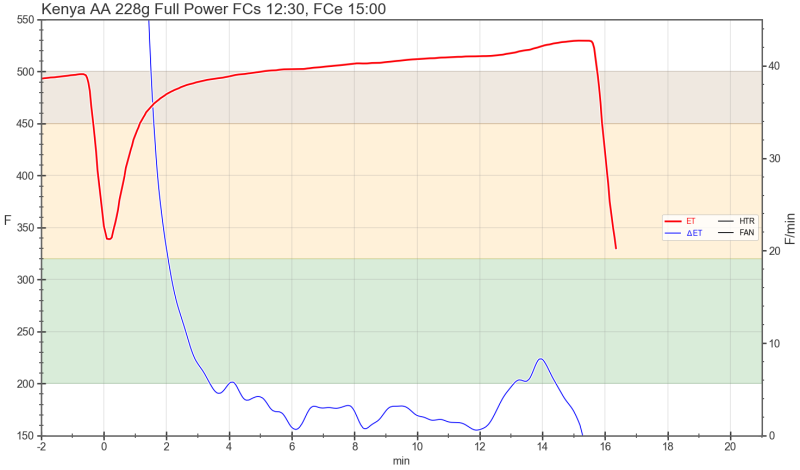

First off, I have modified my roast profile on the Gene, following a recommendation from BoldJava on HomeBarista.com: <Quote>You are working too hard with it. Preheat to 474 thermostat setting for a washed bean (5* lower for . E-Stop. Add beans. Re-start. First crack should occur between 8 and 9 minutes. Run 2 min for a washed after FC; 1:40 for a natural. Drop and cool externally.</Quote> With my machine and environment, first crack occurs between 12:00 and 12:30 minutes. The first crack is detected from the Artisan ROR plot of the Environmental Temperature probe. I am hearing impared, have never been able to hear first crack, and being able to see it is wonderful. I am attaching the Artisan plot of today's roast for reference. See what you think!

SkipG attached the following image:

Gene Cafe (modified), Kalita Pour Over setup.

|

|

|

|

| allenb |

Posted on 11/29/2021 1:27 PM

|

|

Administrator  Posts: 3869 Joined: February 23, 2010 |

That's great news! A sagging RoR as long as no power adjustments are made at that time is definitely a great way to know when 1C is starting and this could be a big help to others with various style roasters where lots of noise makes it impossible to hear the cracks.

1/2 lb and 1 lb drum, Siemens Sirocco fluidbed, presspot, chemex, cajun biggin brewer from the backwoods of Louisiana

|

|

|

|

| renatoa |

Posted on 11/29/2021 2:30 PM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Especially for the Gene case, most Gene owners are reducing the power on the final approach to FC, exactly for the reason to avoid this RoR bump  Not sure how happy will be they to tell keep the power unchanged, just for the RoR detection... that is hard to be noticed on a Gene display, due to sluggish response of the embedded exhaust sensor... So this remains a feature of the hardcore Gene users, accepting modding their machines. |

|

|

|

| SkipG |

Posted on 11/30/2021 4:01 AM

|

|

Newbie  Posts: 11 Joined: April 16, 2021 |

Here's an Artisan graph of the PreHeat curve for the Gene at full power to 474F. Thermostat set to 482F to prevent heater cutoff.

SkipG attached the following image:

Gene Cafe (modified), Kalita Pour Over setup.

|

|

|

|

| renatoa |

Posted on 11/30/2021 5:09 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Please, if possible, perform the same measurement at the heater output, there is a different story. 320C/600F in less than a minute, with Gene heater protection cutting at 360C/680F. Measured myself when repairing a Gene last week. Mains voltage was 234V. I see a big problem when this uber-hot air blows directly in beans, in the half period when the glass is in the position where most beans are at the heatgun side... |

|

|

|

| addertooth |

Posted on 08/04/2022 8:55 PM

|

|

Newbie  Posts: 19 Joined: August 01, 2022 |

This is a 9 month old thread, but still one of the more recent Gene Cafe threads. I have been looking at these kinds of metrics, but using a different measuring method. I have a type K thermocouple with a very fine end which is put in the chaff collector to monitor Exhaust Gas temperature at that point. I also have an Optical Pyrometer which is used to measure EXTERNAL drum temperature. I always felt the digital temperature display on a Stock Gene not very diagnostic. It appears to have a fairly high mass (high lag) reading come from it. I have started transcribing external drum temperature and exhaust temperature on intervals of one minute. My dataset is only about 5 roasts at this point; more data is needed to confirm what it looks like is observed. There does seem to be a flattening of the Rate of Rise (ROR) which occurs during first crack. The ROR will be on a nice upward trend before First Crack (FC), but when FC hits, the ROR flattens out a bit. The challenges with my temperature measurements are two-fold. For the optical Pyrometer, to get expected and consistent values, it must be shot at the SAME spot on the drum, as the beans are in full contact on the other side of the glass. This means you have ONE shot at getting a good read per rotation of the drum. For the type K thermocouple connected to the Fluke meter, it is sensetive to where the end of the probe is placed in the chaff collector. If it is too near the exhaust of the main body of the Gene, you see higher temperatures which more strongly reflect heater cycles. If you are off that port by an inch, you see a greater interaction with the state of the beans (specifically the event of first crack). Or, in other words, the cooling effect from the water released from the beans during first crack, has a more pronounced cooling effect as read by the thermocouple. Most likely, I will end up drilling a hole in the chaff collector a bit off the axis of the port which vents the hot air into the chaff collector. This will allow repeatable placement of the end of the type K thermocouple probe each time. I will probably mark the outer sheathe of the thermocouple so I can repeat the distance it is inserted as well.

addertooth attached the following image:

Edited by addertooth on 08/04/2022 9:02 PM |

|

|

|

| renatoa |

Posted on 08/05/2022 2:08 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

The air exhaust temperature monitoring IN REAL TIME is a very good mean to anticipate the FC, maybe the best. Yeah, the Gene display is averaged for at least one minute window... too slow for this purpose. The rise you see in the attached graph, the orange curve, happens always for any roasting method with constant airflow. For my setup it is about 15 seconds before the audible cracks. Monitoring glass temperature for Gene don't give you a relevant info, too much thermal inertia. Same for beans measurement using IR, because passing of radiation through glass, and also beans surface irregularities. As you can see from the graph, that moment happens fast, so a measurement per second would be recommended, which is faster than reading on a meter and typing value in excel. And also watch beans color, to decide drop time... There was a roasting software called RoastLogger, able to "read" values on a meter display using a camera and OCR recognition, the freeware edition should be available for download somewhere. ~~~

renatoa attached the following image:

|

|

|

|

| renatoa |

Posted on 08/05/2022 5:23 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Given your engineering background you specified in the hello introductory post, I would perform a complete hack at both sides: - heater controlled continuous by a variator, not on-off cycles - real time exhaust temperature measurement/logging, you don't need bean temp for perfect roasts. There were incomplete attempts of such mods/hacks on the internet, since this roaster was been launched, maybe it's time for a complete good solution  We are here to help ! |

|

|

|

| addertooth |

Posted on 08/05/2022 7:38 AM

|

|

Newbie  Posts: 19 Joined: August 01, 2022 |

Eventually, some form of switching-supply control for heat may be tackled. I see a couple varables which must be tackled first. The "loose nut behind the wheel" (in car racing that means the driver/operator). I need to improve my understanding of the roast process, and gain a larger data-set. A better understanding will ensure the right heat, is applied at the right time. There needs to be better logging of the temperature with a finer granularity. For that, I am currently leaning towards an Arduino or Raspberry Pie. Perhaps it will even have L.E.D. indicators which illuminate at the end of dehydration phase, first crack, and second crack. My wife likes Decaf coffee, and detecting "full yellow" is much more difficult on those beans. As previously discussed, hearing the Crack on some beans are quite difficult as well (even when using the cardboard tube trick). After those two issues are better optimized, then a second varable (control of heat generation), will become more valuable. For the moment, I am even keeping batch size matched within a single gram, to keep thermal mass as constant as possible. The unrestrained varable of heat absorption rate of the beans (as well as moisture content of the beans), collude to ensure there will always be significant variations in roast times, and when important stages occur (full yellow, First Crack, etc). |

|

|

|

| addertooth |

Posted on 08/05/2022 7:57 AM

|

|

Newbie  Posts: 19 Joined: August 01, 2022 |

Renatoa, Thank You for posting the graph. It has a lot of useful information in it. It is similar in Envelope to what I am seeing. What kind of roaster was it on? |

|

|

|

| renatoa |

Posted on 08/06/2022 9:54 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

machine is turbo oven (halogen) lid, on top of a custom oven. Regarding the "loose nut..." you are worrying too much, because both our machines are the easier to work with, due to the heat source, majoritary convective hot air. There is no or little radiation, and not at all the much controversial "contact" transfer. For such machines control strategy, the most relevant discussions are in this thread, and the other thread linked: https://homeroast...post_73942 You will find that the most important factor is a good precision and reproducible heat source, before any logging. If you calibrate the relationship between power % and the hot air temperature, supposing that ambient is constant, then the only need for temperature monitoring is the FC detection, not for watching to curve allure. That's because you have nothing to control, the natural curve do its magic alone... check again the graph for the red curve, it's the power level, see how constant it is for the second half of the process? That's why I insist that a Gene mod should start with other heater control as the first step. Some fellows I helped locally to do this mod stopped any further improvement, they don't feel any need to monitor the hot air output, as pleased are about the results...  However, I read somewhere a small detail that raise an exclamation sign about an important factor: the constant ambient temperature ! Roasting outside, or even in an unheated garage, summer or winter, requires serious corrections of such control approach... 3-5 Cels degrees shift of ambient temp equates to about 1% of power control, or 15-30 seconds of FC moment. |

|

|

|

| addertooth |

Posted on 08/07/2022 12:15 PM

|

|

Newbie  Posts: 19 Joined: August 01, 2022 |

Renatoa, The ending of your post hits upon one of my limitations. I roast outside. I normally try to wait until the Arizona temperature has risen to a mid-80s degree F point to start my roasting. After the first roast, even though I do a cool-down cycle, there is residual heat in the roaster which cannot be discounted. Compounding this issue, is the fact the ambient temperature continues to rise through the morning, often 20 degrees higher. Perhaps this is why I focused on monitoring temperatures, as absolutely controlling the amount of heat energy is not entirely possible (applied+ambient+residual). Knowing the heat allows me to turn up/down the temperature setting on the Gene to get it in the zone. I already do a multiple temperature step roast. Unlike many gene roasters, I just don't crank it up and let it run to the end. I have noticed certain benchmarks for full yellow and first crack. The exhaust temperature is typically 305 to 308 F at full yellow (without regard to what temperature I am set to on the Gene. Drum temperature (as measured by the optical pyrometer) is in the 342 to 346 at first crack. But, I continue to increase my dataset log, as a limited set of roasts represents a "trend", but is not to be taken as Fact. I do so few roasts into second crack due to the beans I roast. So, I have no "trend" for second crack yet. |

|

|

|

| addertooth |

Posted on 08/23/2022 9:04 AM

|

|

Newbie  Posts: 19 Joined: August 01, 2022 |

A brief follow on. More data has been captured. I confirmed that location of the thermocouple probe is vital to tying full yellow and first crack via an "absolute temperature" read by the meter. It will simply have to be fixed into a specific location to give a meaningful and repeatable result. Even with the position changing (due to removing the chaff collector to dump out the chaff), a trend has been noted of the probe's measured rate of rise flattening (or when in some positions dipping) at first crack. (data set is about 11 roasts). I was reluctant to drill a hole in the chaff collector, which would ensure a consistent placement, but I will simply have to accept this should I wish to use absolute values, as versus a "change/flattening in the Rate of Rise curve" as an indicator of First Crack. Now, on an interesting side-note. I got a more "pro-grade" opitical pyrometer. As per previous discussions, the external drum temperature is taken at a specific spot on the drum each rotations. It is well understood that the external air is cooling the outside of the drum, while heat on the inside is warming it. The optical temperature is always measure where the greatest bean contact is ocurring. The new pyrometer give more consistent and repeatable readings. Full Yellow always seems to happen at a reading of 300 degrees F, and First Crack seems to always happen at 340 degrees F. I realize the beans are actually hotter, but as long as a system of errors are consistent, they can be "adjusted for". i.e. a car speedometer that is always 7 percent low, can be corrected for, to get actual car speed. I realize the relationship is known to be non-linear, i.e., the higher the internal temperature the greater the error in the exterior temperature. I still have no data for second crack, as darker roasted beans do not interest me much. Edited by addertooth on 08/23/2022 9:45 AM |

|

|

|

| renatoa |

Posted on 08/23/2022 1:46 PM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

This relationship could depend also on beans specifics. The natural processed beans are darkening different than the washed. Some african origins, like Tanzania, preserve the peel until the middle of development, so they are silver in the moment of FC, surely will read a lot different than other beans. Imo, is much safer to stop worrying and learn to love the exhaust air temperature, it contains all info you need to judge a roast. |

|

|

|

| addertooth |

Posted on 08/23/2022 8:26 PM

|

|

Newbie  Posts: 19 Joined: August 01, 2022 |

Renatoa, I am inclined to believe you, but first I must do my part and get the thermocouple in a repeatable location. Every time I moved it to empty the chaff, what temperature it showed at first crack changed. |

|

|

|

| renatoa |

Posted on 08/24/2022 2:39 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

I would replace the original Gene RTD sensor with a TC, it is mounted simply by pressure, in a 4mm bore in the plastic body. |

|

|

|

| addertooth |

Posted on 08/25/2022 7:31 PM

|

|

Newbie  Posts: 19 Joined: August 01, 2022 |

I thought an RTD is normally a resistance-based temperature sensor, as versus a thermocouple, which makes a voltage proportional to the temperature. |

|

|

|

| renatoa |

Posted on 08/26/2022 1:56 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Yes, you are right. The Gene sensors have resistance, in the hundreds kO ballpark, unlike a TC that is a shortcut, two wires welded together. If lower resistance, then could be Platinum RTD, but over 100k is other technology. Anyway, replacing the probe is not enough, you need your own measurement system, much faster, i.e. with less averaging than Gene, and capable to show also rate of change. |

|

|

|

| addertooth |

Posted on 08/30/2022 9:36 PM

|

|

Newbie  Posts: 19 Joined: August 01, 2022 |

I drilled a hole in the chaff collector to accept a repeatable placement for the type K thermocouple, which is plugged into a Fluke 87 series V meter. It updates about ten times a second. The data has been more repeatable since this change has been done, but that only included 6 roasts. I am considering building a pre-amp and feeding the output into my digital dual trace storage scope in the future. But, that is likely weeks/months away. More likely I will end up taking the time to use an Arduino or a Raspberry Pi to perform the same task. I am still collecting data, but it definately shows a dip/flattening in the rate of rise at first crack. After first crack is over, the temperature starts climbing up at a more expected rate. Once a more complete data set is available, I will post a better refined description to what is seen. I only make use of data from roasts where the first crack is well defined and heard. Some of the beans I have roasted (and especially *some* peaberries and decafs are very quiet at first crack, which leaves me having to look at visual queues to determine when first crack occurred. Those more questionable segments of data will not be included for primary determinations, but will likely be anectdotal data. |

|

|

|

| renatoa |

Posted on 08/31/2022 2:56 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

You should consider contemporary solutions of using dedicated ICs for TC or Pt sensors signal processing, like MAX31856 or MAX31865. Building from the scratch a sensor preamp or using a bare ADC is like reinventing wheel again. Plus you need to compensate a lot of non linear things that are already handled by the chips above. Also, Arduino/ESP based roasting software already exists, with support for the chips above, take a look at TC4(ESP) |

|

|

|

| addertooth |

Posted on 09/01/2022 8:32 AM

|

|

Newbie  Posts: 19 Joined: August 01, 2022 |

I thought the TC4 was mostly geared toward air-popper style roasters (fluidized bed). I took a peek at it about a week ago. It seemed like most the crowd using it were modified air poppers. By the way, thanks for the suggestion of the Maxim Chipsets. I have always liked their product lines. They make great niche chips which fulfill a specialized role. I remember when their big market was their switching regulator chips. They have been at it a long time. |

|

|

|

| renatoa |

Posted on 09/01/2022 11:36 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Stoooppp !!! Severe misunderstanding alert !  We can't go forward without clarifying this first  Kidding, but roasting is roasting, the data acquisition/logging, computations and logic behind graph plotting is the same for any and all machines! I can't bet, but I am pretty sure that in the whole "Dataloggers/Controllers/Rate of Rise Meters" subforum there is such thing, I mean an electronics project related to roasting, developed mainly for a specific machine/technology. Maybe for Gene  |

|

|

|

Page 1 of 2: 12

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman