Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [375] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 2

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,393

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

Page 1 of 2: 12

|

|

These are the specifications of the roasting machine that took a year to build

|

|

| Yasu |

Posted on 05/11/2022 9:52 PM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

The specifications of the roasting machine, which took a year to build, are summarized as if it were a manufacturer's brochure. I am posting this to ask for your opinions. Any opinions would be appreciated. YASU-3000 Hybrid-Roaster Specifications Capacity 1.1kg-3kg 2.Heat Source Gas/Electric Hybrid Heat Source 3.10kW gas burner (LPG Gas)-variable control by program? 4.LPG combustion temperature cascade control with flow meter 5.proportional valve 6.3kW hot air generator 200V - follow-up control according to profile Air Flow 1.Roast fan/cooling fan: 11m�/Min@ 1100 Pa 200V-200W 3P Electrical 1.100V 2P 500W 2.200V 2P 3000W Control 1. Artisan Software 2.Touch panel operation on PC screen 3. Full automatic operation / Partial manual operation 4.Profile roasting defaults from proven recipes Profile Plotting 1.Recorded data - All 9 data items can be trended, graphed, and logged. 2.BT - Bean temperature (BT-SV bean temperature target) 4.ET - Exhaust Temperature 5.Delta BT (ROR) 6.IT - gas burner combustion temperature 7.IT-SV gas burner combustion temperature (target temperature) 8.LPG - combustion gas flow rate 9.PA - Micro-pressure in the drum 10.CO concentration - Carbon monoxide concentration in roasting exhaust 11.Drum temperature - Digital emissivity thermometer 12.ROR (PV-SV) Drum 1.Cast iron drum 2.Rotation speed 10-70RPM Variable operation Special Specifications (1) Exhaust fan pressure control Instead of directly adjusting fan speed in revolutions per minute, air pressure is now directly adjusted in pascals. (Inverter by PID) This means that perfect drum pressure can be maintained throughout the entire roasting. Normally, ?the inlet air density changes with temperature, so the drum pressure is constantly changing. This system cancels these fluctuations by automatically adjusting the fan speed to match the desired drum pressure. The result is perfect consistency regardless of air density. Also, your special roasting technique can be easily programmed, such as automatically setting a low air flow at first and automatically increasing the air flow after five min, through PC settings. (2) Automatic gas flow control By moving the combustion temperature slider on the PC touch panel, the flame can be increased or decreased for precise repeatability every time. While most burners rely on subtle valve manipulation, the ROASTER allows the user to control the required gas flow by simply setting the combustion temperature. The ROASTER calculates and controls the required gas volume once the combustion temperature is determined. In the case of the exhaust fine pressure adjustment described above, a typical ROASTER will increase temperature when exhaust pressure is lowered and decrease temperature when exhaust pressure is increased. However, the ROASTER automatically operates the proportional valve to keep the combustion temperature at a constant level even if the exhaust air volume is changed. The gas burner is located a short distance away from the drum, and a shielding plate makes it easy to get the flavor of a semi-hot-air roaster or a hot-air roaster. (3) Drum speed control The speed at which the drum rotates in the roaster can be fully controlled. Drum speed can greatly affect the amount of convection/conduction heating, allowing you to adjust the flavor profile of the roast to your preference. (4) Drum temperature measurement (with digital radiation thermometer) Have you ever wondered about drum temperature??Even when you think preheating is finished, the drum The drum may not yet be at the required temperature even if you think it has finished preheating. ?Cause of not roasting according to the recipe. Gas is suppressed, but it gets out of control more and more. ?Roasting proceeds due to the stored heat in the drum. Have you been dealing with these things by experience so far? This roaster is equipped with a non-contact radiation temperature sensor to constantly monitor the drum temperature. Add a new drum temperature to your existing conditions and enter a new era. Roast Program (fully integrated with Artisan) Operators can switch from full manual to various levels of automation at any point during the roast. Roast at full profile during the drying phase and switch to manual mode only after the first crack. There are various methods of automation. Automatic sequential control (reproduces the environment around the beans in time) In automatic mode, you can copy exactly what was done in the previous roasting at specific settings (combustion temperature, drum speed, internal drum pressure). If you roasted manually in a previous roast, the automatic function will faithfully reproduce the same settings. Profile control (design in Artisan, profile roasting with stored data) In the profile mode, exhaust pressure and gas combustion are controlled by sequential control with a combustion program that matches the time axis, but the hot air generator takes advantage of the hybrid to fine-tune the temperature profile of the beans themselves while roasting. This function was developed in response to the fact that many models are used in manual mode because they inevitably do not want to run out of control due to profile control. ?This craftsman can perform the roasting control of your dreams. Manual control (for sample roasting, etc.) All functions can be freely selected between automatic and manual. Make the best recipe with the technique you have. Of course, the operation at that time The artisan will be watching over you the whole time and will reproduce the recipe for you the next time. All of these roasting programs are controlled by Artisan. You will discover that Artisan is not just a logging software, but the heart of ROASTER. Each sensor RS-485 Modbus PC

Yasu attached the following images:

Edited by Yasu on 04/20/2023 8:40 PM |

|

|

|

| renatoa |

Posted on 05/12/2022 7:32 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Quote You will discover that Artisan is not just a logging software, but the heart of ROASTER. That overloaded panel contradicts this statement, imo... People approach Artisan roasting hoping to forget about displays and knobs. usually.  |

|

|

|

| Yasu |

Posted on 05/12/2022 7:44 AM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

Thank you for your comment. I have added a new image to the artisan? I have put up a new image. These panels are independent so that they can be operated manually even in the event of PC trouble. Since they are connected to the PC via RS485, these panels are disabled when Auto is selected with the artisan button, and the PC-artisan control is used to control the panels. |

|

|

|

| renatoa |

Posted on 05/12/2022 8:13 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Kidding, I didn't denied it can be operated both ways, but the control panel really looks intimidating even for a factory operator  I can't remember if I ever seen another roaster control panel so loaded. Can we hear more about the hybrid nature of the roaster? It's similar to a Loring, or how is the heat produced and transferred to beans ? Edited by renatoa on 05/13/2022 2:42 AM |

|

|

|

| Yasu |

Posted on 05/12/2022 8:28 AM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

Thank you for your question. I got here with a lot of difficulty. At first we tried to control the gas combustion directly from the temperature of the beans, but the feedback was slow and we could not control it well due to disturbances such as radiant heat from the drum depending on the temperature range. So we decided to use a hybrid of gas and electric hot air generator. First, the electric hot-air generator was fixed at 50% output (1.5 kw), and the combustion temperature was adjusted while watching the profile. The combustion temperature at that time is input into the lamp soak program of the omron temperature controller. (This can be done easily from a PC) During the next roasting, the combustion output is controlled by the omron temperature regulator and the roasting proceeds according to the artisan profile curve. However, if there is a subtle deviation (moisture, bean quality, etc.), the electric air temperature generator will use the indicated SV from the artisan's profile curve to make fine adjustments through proportional control. Since it is a fine adjustment, the hot air is controlled by SSR as if it were adjusted by human hands without running out of control as in the case of the PID control that is completely left to the operator. It is still in shakedown and needs to be worked out such as coefficients. (It has only been roasted 4 times, but I think it roasts better than normal.) |

|

|

|

| Yasu |

Posted on 05/12/2022 9:32 AM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

The hot air generator is a large LPG stove with very high thermal efficiency (like those found in Chinese restaurants) surrounded by a vertical stainless steel bowl to serve as the combustion chamber. Since it is installed at a distance from the drum, the temperature outside the drum is kept at about 220�C even when burning at maximum heat power of 10KW for several minutes. ?It was designed with gissen in mind rather than loring. (We did not want to use hot air circulation.)

Yasu attached the following image:

|

|

|

|

| zeece |

Posted on 05/12/2022 12:19 PM

|

|

Newbie  Posts: 6 Joined: March 26, 2007 |

Very cool instrumentation. What sensor(s) are you using to measure the gas flow? |

|

|

|

| Yasu |

Posted on 05/12/2022 12:49 PM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

I use a proportional valve with a small built-in flow meter.? I give it a 4-20ma signal to indicate the flow rate of LPG to be flowed, and it controls the valve to the required position while measuring the flow rate by itself. Since the maximum specification is 0-10liter/min, simply provide a signal such as 12mA for 5liter/min or 7.2mA for 2liter/min, and the valve will control itself and display the flow rate. The 4-20 mA signal is issued by the FUJI temperature control, which controls combustion, by receiving the temperature indicated by the lamp soak program in the omron temperature control and calculating the necessary gas volume by PID control. This is the so-called cascade control. This was another difficult part of the project. Instead of using a single temperature controller to control the temperature, it was better to use two separate temperature controllers, one to calculate the required temperature and the other to calculate the required gas volume. One reason is that OMRON's lamp soak control can be easily done with PC software (which I am familiar with) https://www.fa.om...mily/3289/ Edited by renatoa on 05/12/2022 3:02 PM |

|

|

|

| espresoman |

Posted on 05/13/2022 2:17 AM

|

|

Newbie  Posts: 2 Joined: May 02, 2021 |

Hi! Nice work! We want more pictures or videos if possible. Toper Cafemino 1kg + TC4s Renato logger

|

|

|

|

| Yasu |

Posted on 05/13/2022 3:40 AM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

Thank you for your request! Unfortunately, My roasting machine is located in a secret hideaway deep in the mountains and we cannot roast every day. (If I tried to roast at home, my wife would break the roaster for being too noisy and disturbing the neighbors...) ) I would like to try filming the next time, but I'm too busy taking data and I don't have time to do so. How can I upload the video afterwards? I don't want to use youtube uploading... |

|

|

|

| renatoa |

Posted on 05/13/2022 4:17 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

You can try vimeo or dailymotion. But youtube if you tag your video as "not listed" should be enough safe for your privacy... or what else worry you about youtube? We don't have here a video straeming/hosting system, only files attachment of a limited size. |

|

|

|

| Yasu |

Posted on 05/13/2022 6:35 AM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

The roasting machine is at our hideaway, but the PC is at hand, so here is the artisan screen. Input from the sensor is RS485 with full 8CH. 1CH:BT 2CH:ET 3CH: heater output 4CH: Combustion temperature 5CH: Drum outer temperature 6CH: LPG flow rate liter/min 7CH: Drum internal pressure (PA) 8CH: CO concentration Output can also be directed to the temperature regulator and other devices using RS485 with a button set from artisan. The button settings are IT? : Combustion temperature IT-S: Shift of combustion temperature (fine adjustment) BT-S: BT temperature shift PA: Drum internal pressure? GUN AT/MT: Automatic/manual hot air generator GUN %* Output of hot-air generator IT MT/cascade: Shift of combustion temperature artisan/omron PID1-7: Switching between 7 preset BT PID values Above.

Yasu attached the following images:

|

|

|

|

| Yasu |

Posted on 05/13/2022 7:29 AM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

Here is a video of a previous test roasting. Edited by renatoa on 05/13/2022 7:42 AM |

|

|

|

| Yasu |

Posted on 05/14/2022 10:54 PM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

I have some images from when I was struggling with the PID setting values before, so I will upload them. When the PID setting could not be determined, I could not cope with the feedback delay and hunting occurred. It's not perfect yet, but I found a setting to make and still trace the ROR curve of the tinker with the profile design of ARTISAN. At first I was using a button to switch the PID setting to get the data, but I didn't want to waste coffee beans, so I was looking for a dummy PID setting to get the data at a lower temperature. However, I took a detour until I realized that it was important to match the goahed seconds of the Artisan control to the response of the roasting machine itself, not just the PID setting.

Yasu attached the following images:

|

|

|

|

| renatoa |

Posted on 05/15/2022 3:00 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

PID algorithm is simply not appropriate for following a moving target, wasn't been intended for such task. The whole math theory posted on the internet and code implementations are based on the assumption of reaching a point, and maintaining there. And also can't work without over/under shoots, thus oscillations, that are ruining the RoR curve. Good for boilers, fixed temp processes as beer brewing  |

|

|

|

| Yasu |

Posted on 05/15/2022 5:23 AM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

Yes, if you just want to follow time changes, you can do it by switching PID values in the temperature range, but it is quite tough because of the drying, cracking, chemical reactions, exotherm, etc. involved. However, if you want the gas combustion temperature to be sequence-controlled (ramp soak to a predetermined temperature every min) and However, we are almost there with a hybrid strategy of sequence control of gas combustion temperature (ramp soak at a predetermined temperature for a certain time) and PID control of fine adjustment with a warm air generator, so we will do our best. |

|

|

|

| Yasu |

Posted on 06/06/2022 4:29 AM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

Hello. I got a request to show you a video. This is a shot of me adjusting the burner control. I took this from Artisan's PC screen. The sliders on the left are PA = Pressure setting in the drum (SV)? IT = Burner combustion temperature setting (SV) The slider on the left is PA = pressure in the drum and IT = burner combustion temperature. The input display on the right is ET = Exhaust temperature Heater = hot air generator KW (off at this time) IT = Actual combustion temperature (PV) Drum PV = Drum outer circumference temperature (infrared) (PV) LPG Rate = Burned LPG (?/min) PA = Measured drum internal pressure (PV) Here you can see that the pressure inside the drum is changed by the slider ? fan speed PID control by the inverter ? pressure inside the drum changes ? LPG gas flow rate also changes ? combustion temperature is controlled to remain the same. (When lowering the temperature, the response is a little sluggish due to the heat capacity, but I think it is acceptable.) It can also be seen that the exhaust temperature remains almost at 190�C even when the airflow is doubled in the case of the up-side control. Edited by Yasu on 06/06/2022 4:48 AM |

|

|

|

| Yasu |

Posted on 06/06/2022 5:19 AM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

Of course, it is usually more often used to vary the LPG flow rate to the combustion temperature measurement to achieve the targeted temperature when the combustion temperature is varied Edited by Yasu on 06/06/2022 6:22 AM |

|

|

|

| CK |

Posted on 06/06/2022 11:06 AM

|

|

1/2 Pounder  Posts: 252 Joined: December 07, 2018 |

Looks like a sophisticated setup... I like it! Hope you get good results from all your efforts. Thanks for sharing. |

|

|

|

| Yasu |

Posted on 06/07/2022 1:23 AM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

Hello, CK. Thanks for taking a look at the write-up. I've come this far while building a roaster because I enjoy building the roaster itself, but others have asked, "What is the purpose of building it?" Many people ask me, "What is the purpose of your roasting machine? I think that I am making it in order to realize many dreams. STEP1 First of all, we build a roaster that can be heated in the way we want it to be heated, and that can record that condition. ?We need something that can reproduce the temperature, air volume, and rotation speed around the beans on a time axis as we want. STEP2: To make the beans themselves (temperature, chemical reaction, and dryness) change on a time axis as desired, and to bake them while changing the conditions of STEP1 with feedback. ?(A roasting machine that can cancel differences in bean type, moisture content, and year, etc., to produce the best roasting) STEP3 Create a correlation performance between this roaster and other roasting machines and roasted items, and make it a roasting simulator that can roast the same items for roasters and roasting stores around the world. STEP4 Reproduce the world's coffee that you have drunk with your own tongue and roasting machine. We designed the roasting machine with these dreams in mind. It is still STEP1, but I am enjoying every day to realize my dream. |

|

|

|

| Yasu |

Posted on 06/09/2022 2:44 AM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

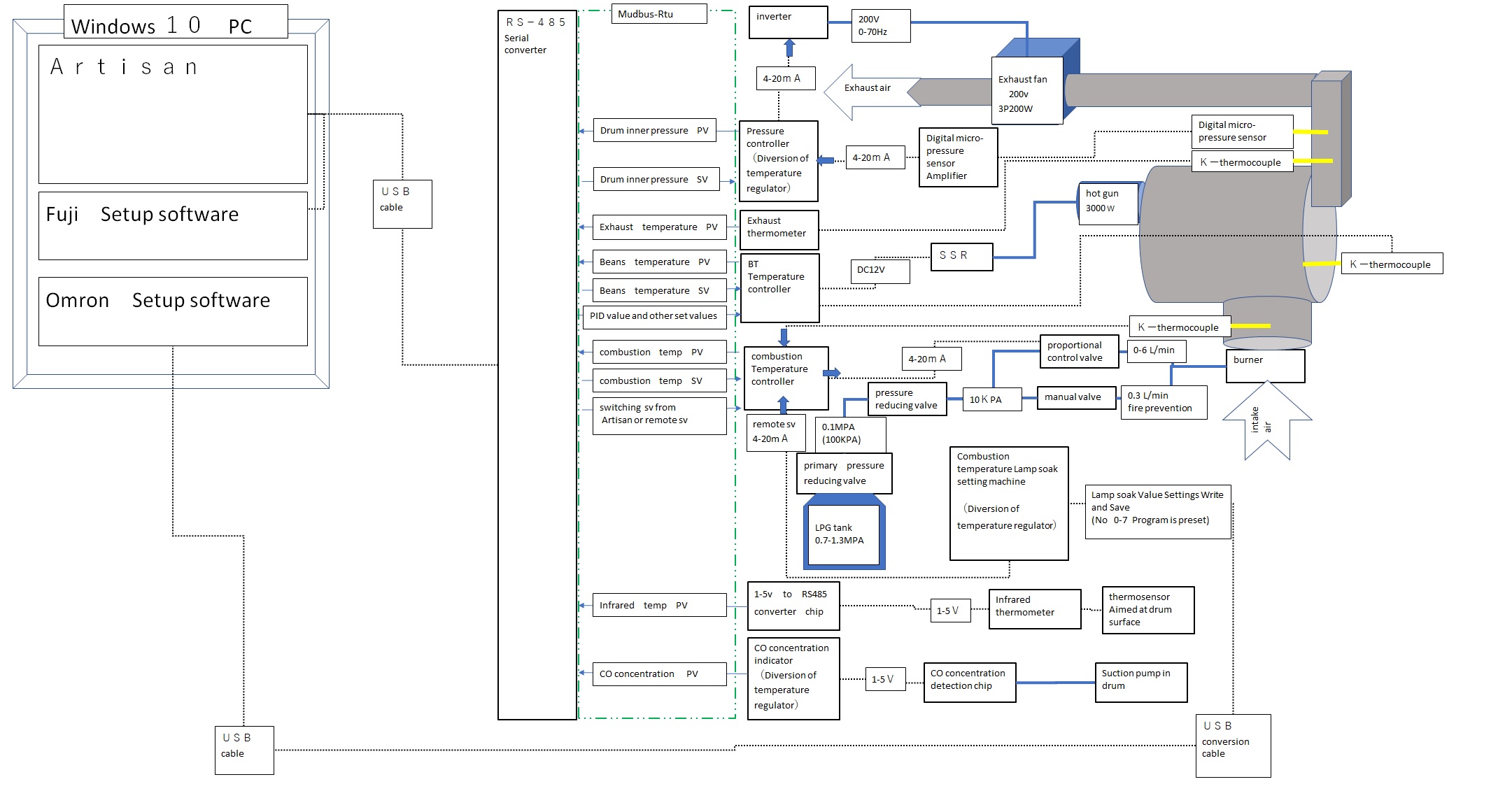

Hello, everybody. My roasting machine has so many devices that even I can't get people to understand how complicated it is, so I made a hardware wiring diagram and uploaded it here. (I didn't include the independent meter controls such as drum rotation that are not linked to Artisan). I would appreciate any comments or advice you may have.

Yasu attached the following image:

|

|

|

|

| renatoa |

Posted on 06/09/2022 3:11 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

The hard question ... is really necessary this complication degree ? That also bring lower reliability, is just a matter of statistics, the increased number of parts led to lower life of the whole assembly... Actually, you can roast very accurately with just a stable and reproducible heat source, nothing else, even without measurements, just an initial calibration. |

|

|

|

| Yasu |

Posted on 06/09/2022 9:04 AM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

I know, it's true. But my dream is to reproduce the differences in taste between various roasting machines (for teaching purposes) (why do I swear by the same profile?) and enjoy the differences in taste. I will check the amount of airflow and heat per bean by manufacturer and compare the ratio of heat transfer, radiant heat, and convection heat. Please help me even if it is a pain in the ass. Professionals would never do this because profitability is important. But we are amateurs, so we have the privilege of doing whatever we want as long as it is fun. Please let us play. |

|

|

|

| renatoa |

Posted on 06/09/2022 10:31 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Amateurs roast too little to gain the knowledge of a professional. Sure, the hobbyists can be more picky, but this is not enough. Exercise is needed, roasting every day, and more than five origins in the warehouse. The most sophisticated electronic jobs I did for coffee roasting were done to assist professionals in my community, not for my own usage. Things like exhaust pressure monitoring in Artisan, or others same level. Some of those professionals are interested to achieve "perfect" roast, at least equal as for the profit. Edited by renatoa on 06/09/2022 1:52 PM |

|

|

|

| Yasu |

Posted on 06/09/2022 12:06 PM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

As an amateur, my biggest problem is that I cannot increase the number of times I roast. In my roasting experience with this roaster, I have roasted real coffee beans only six times. However, I have been able to accumulate data from all the roasting machines, so I spend a lot of time analyzing the hot air, the amount of air, the drum temperature, and other factors that make a difference in the temperature of the beans at each roasting to find a correlation. Professionals get the best profiles from hundreds or thousands of roasts, but I don't have that chance. So I'm putting it on the way I'm doing it now. To surpass in taste the professionals who have only roasted 6 times. Let me play. |

|

|

|

Page 1 of 2: 12

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman