Login

Shoutbox

You must login to post a message.

renatoa

07/26/2024 3:49 PM

Bill grubbe and Jk,

allenb

07/26/2024 5:15 AM

Spiderkw Welcome to HRO!

renatoa

07/24/2024 8:31 AM

ramiroflores and John123,

?

?

?

?renatoa

07/21/2024 1:18 AM

, Luislobo

, Luisloborenatoa

07/19/2024 11:28 AM

Koepea,

Forum Threads

Newest Threads

Skywalker roaster modsBackground Roast Iss...

Hello from Arkansas

TC4ESP

Green coffee reviews

Hottest Threads

| Skywalker roaster... | [376] |

| TC4ESP | [115] |

| War on Farmers by... | [47] |

| Adventures in flu... | [26] |

| Hello! (soon) Roa... | [17] |

Donations

Latest Donations

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

dmccallum - 10.00

JackH - 25.00

snwcmpr - 10.00

Anonymous - 2.00

Anonymous - 5.00

Users Online

Guests Online: 5

Members Online: 0

Total Members: 8,394

Newest Member: Bill grubbe

Members Online: 0

Total Members: 8,394

Newest Member: Bill grubbe

View Thread

Who is here? 1 guest(s)

Page 1 of 2: 12

|

|

These are the specifications of the roasting machine that took a year to build

|

|

| Yasu |

Posted on 06/09/2022 2:44 AM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

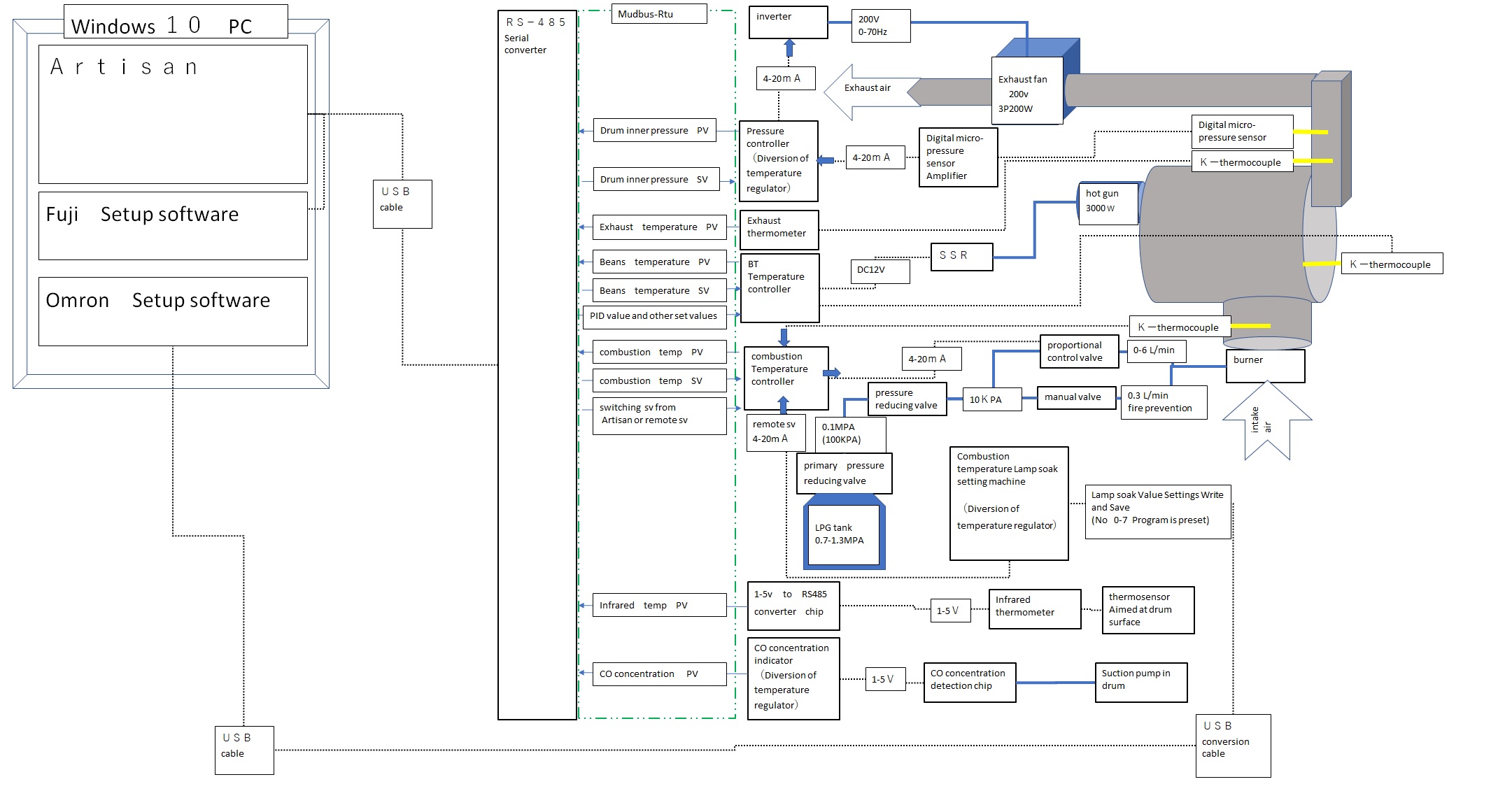

Hello, everybody. My roasting machine has so many devices that even I can't get people to understand how complicated it is, so I made a hardware wiring diagram and uploaded it here. (I didn't include the independent meter controls such as drum rotation that are not linked to Artisan). I would appreciate any comments or advice you may have.

Yasu attached the following image:

|

|

|

|

| renatoa |

Posted on 06/09/2022 3:11 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

The hard question ... is really necessary this complication degree ? That also bring lower reliability, is just a matter of statistics, the increased number of parts led to lower life of the whole assembly... Actually, you can roast very accurately with just a stable and reproducible heat source, nothing else, even without measurements, just an initial calibration. |

|

|

|

| Yasu |

Posted on 06/09/2022 9:04 AM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

I know, it's true. But my dream is to reproduce the differences in taste between various roasting machines (for teaching purposes) (why do I swear by the same profile?) and enjoy the differences in taste. I will check the amount of airflow and heat per bean by manufacturer and compare the ratio of heat transfer, radiant heat, and convection heat. Please help me even if it is a pain in the ass. Professionals would never do this because profitability is important. But we are amateurs, so we have the privilege of doing whatever we want as long as it is fun. Please let us play. |

|

|

|

| renatoa |

Posted on 06/09/2022 10:31 AM

|

|

Administrator  Posts: 3104 Joined: September 30, 2016 |

Amateurs roast too little to gain the knowledge of a professional. Sure, the hobbyists can be more picky, but this is not enough. Exercise is needed, roasting every day, and more than five origins in the warehouse. The most sophisticated electronic jobs I did for coffee roasting were done to assist professionals in my community, not for my own usage. Things like exhaust pressure monitoring in Artisan, or others same level. Some of those professionals are interested to achieve "perfect" roast, at least equal as for the profit. Edited by renatoa on 06/09/2022 1:52 PM |

|

|

|

| Yasu |

Posted on 06/09/2022 12:06 PM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

As an amateur, my biggest problem is that I cannot increase the number of times I roast. In my roasting experience with this roaster, I have roasted real coffee beans only six times. However, I have been able to accumulate data from all the roasting machines, so I spend a lot of time analyzing the hot air, the amount of air, the drum temperature, and other factors that make a difference in the temperature of the beans at each roasting to find a correlation. Professionals get the best profiles from hundreds or thousands of roasts, but I don't have that chance. So I'm putting it on the way I'm doing it now. To surpass in taste the professionals who have only roasted 6 times. Let me play. |

|

|

|

| oldgrumpus |

Posted on 12/06/2022 5:52 PM

|

|

1/2 Pounder  Posts: 225 Joined: July 25, 2012 |

You did a BEAUTIFUL job on your roaster. The heating system principle resembles this video I posted a few years ago on this forum of the Buhler TM60. https://homeroast...o.php?id=7 Clever Coffee Dripper

Grinder: Macap M4 Roaster: Completed drum roaster project photos shown here: Photos https://goo.gl/ph...Da6K4wfqw5 Videos https://www.youtu...Bd1NrdpSUH Build thread https://homeroast...post_38189 |

|

|

|

| Yasu |

Posted on 12/07/2022 11:24 AM

|

|

1/4 Pounder  Posts: 75 Joined: March 27, 2022 |

Thanks for the post. I watched the concept video. My system does not recycle exhaust air, but I think the temperature control concept is the same idea. In the meantime, I've been able to roast according to the profile I drew, and I'm in the process of creating my own favorite recipe. Please let me know more about it. I have recently modified the system so that I can roast while switching between 7 preset PID values with one click, so I can trace the SV and PV values of the BT perfectly. |

|

|

|

Page 1 of 2: 12

| Jump to Forum: |

Powered by PHP-Fusion Copyright © 2024 PHP-Fusion Inc

Released as free software without warranties under GNU Affero GPL v3

Designed with ♥ by NetriXHosted by skpacman